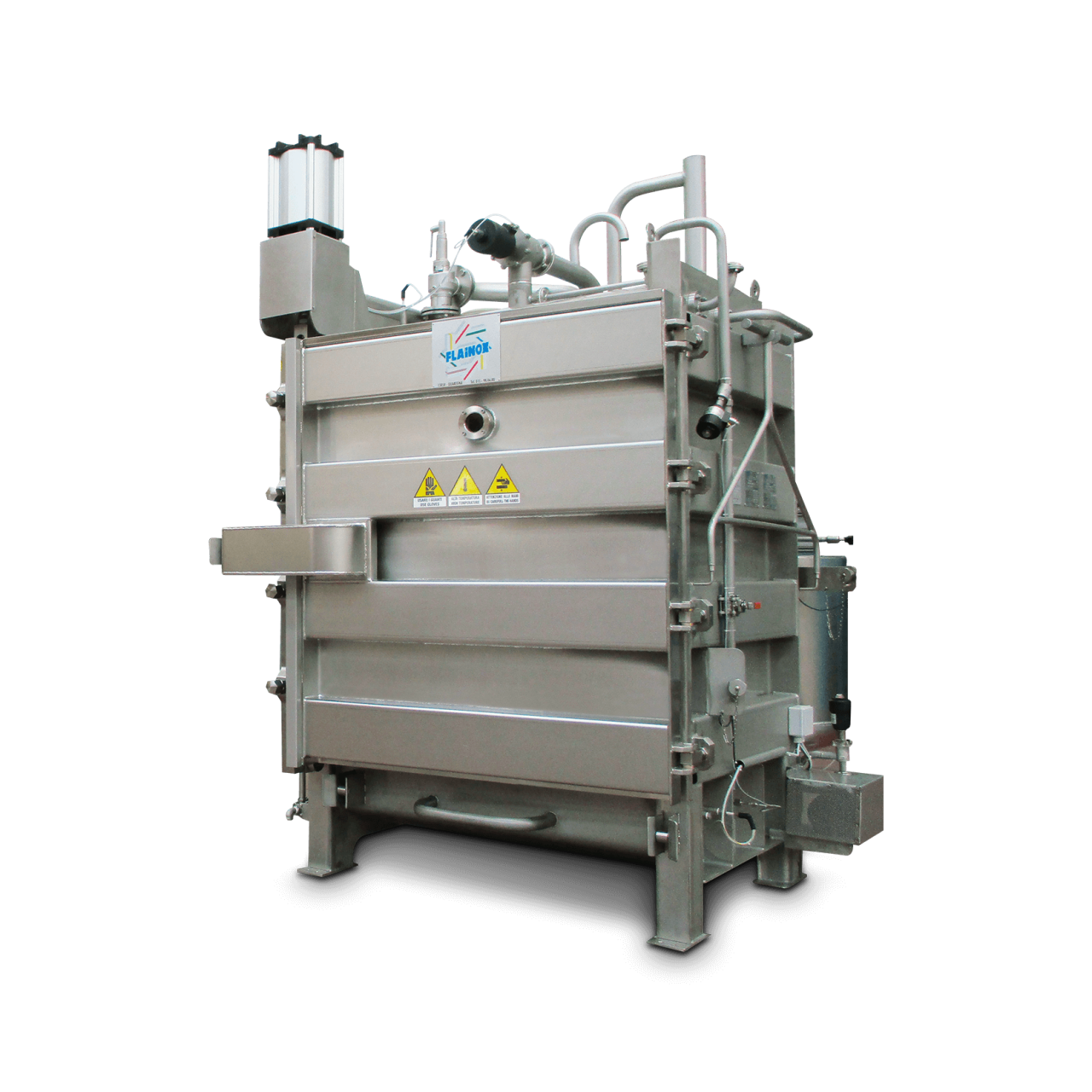

Technical details

• Construction in high thickness AISI 316 / L stainless steel.

• Pressurization with air cushion or external recirculation of the bath.

• Material holder for yarn dyeing in hanks.

• Possibility to equip the machine with devices for reducing of charge keeping the bath ratio constant

• Automatic coupling systems with total replacement of the bath for dyeing large quantities

• Construction according to European standards for pressure equipment (PED) and ASME certification

• FLAINOX Industrial PC with online assistance from remote.